Ergonomics, Insight, Workplace Safety

Ergonomics Reimagined

by Lauren Wandell

When a manufacturing company has a recurrent occupational injury from a task, they have been encouraged to seek out an Ergonomist, but now there are technologies which are helping us to reimagine the effectiveness of ergonomics.

An Ergonomist uses interviews, recording equipment, predictive equations and experiential expertise to evaluate a job or task to identify the high risk postures that can contribute to injury over time.

These postures cause injuries called musculoskeletal disorders. They’re many of the same injuries that occur in athletes, injuries involving muscles, tendons, and nerves. They are injuries that compound over time and tend to have a longer recovery time than acute injuries.

A human ergonomist, however, can only do so much. Human observers have uncovered high risk postures, tasks and jobs that have reduced musculoskeletal injuries and incidents, has saved companies thousands of dollars, and has redesigned work to be safer for future workers.

But it has never felt like a complete approach.

-

- An Ergonomist is brought in only after enough injuries have been reported, and musculoskeletal injuries are notoriously underreported in workplaces

-

- We rely on one or two worker’s perspectives on the amount and duration of their tasks without seeing the population of workers approach for perspective

- Ergonomists make recommendations based on our expertise and predictive formulas. While these are the most informed results of current work observation, the lack of actual data makes it easy for stakeholders to avoid or ignore the recommendations

Now is an exciting time for the Ergonomics industry with the emergence of Industry 4.0.

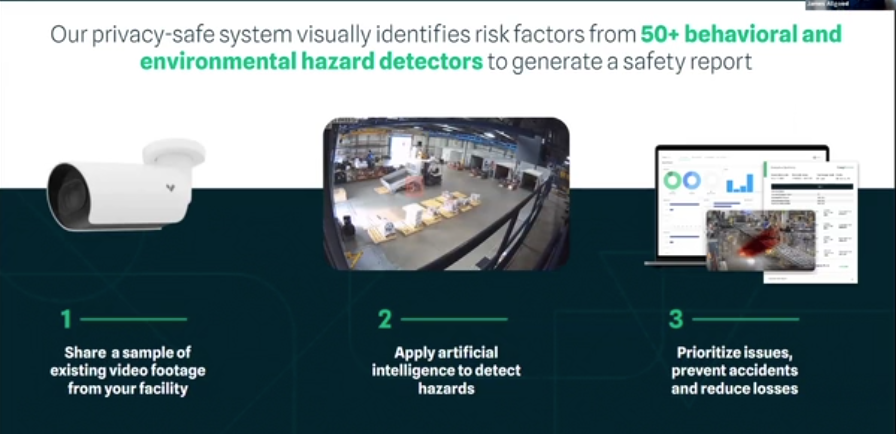

With the emergence of machine learning, computer learning, and AI, the field of Ergonomics has an opportunity to collect actual work posture data.

By developing AI to observe, identify and count awkward postures, prolonged non-neutral postures and repetitive postures, Ergonomists can now access real-time data. This allows the Ergonomist to take a larger perspective on workplace evaluation.

This means an Ergonomist doesn’t have to wait for injuries to accumulate before intervention is warranted. By knowing where high risk work is occurring, we can focus ergonomic evaluations on, not only the postures of work, but the pace of work throughout the day and week, the interaction between workers, the organization of work, and the larger organizational approach to work safety. Now our recommendations come with real data and video review, showing stakeholders what is actually occurring in their facilities and why.

Workers should expect to go home at the end of the day with enough energy to live their private lives. Manufacturing workers put in long hours of physical labor, and in many cases these workers spend most of their lives, 20, 30, even 40+ years doing this work. A truly essential part of working as an Ergonomist is striving to ensure that physical labor doesn’t guarantee a sentence to disability. That’s best for the individual, but it’s also best for the organization as a whole. When a workplace encourages safe work practices and provides safer work, workers can, and want to, work there longer. That means reduced injury, reduced turnover, reduced retraining and hiring costs, and increased morale and loyalty for an organization.